TURNKEY PROJECT MANAGEMENT

We offer you an end-to-end partnership to ensure you get exactly the solutions you need

We offer you an end-to-end partnership to ensure you get exactly the solutions you need

We offer you a one-stop shop from initial enquiry through to finished installation. We partner closely with operators, architects, contractors and consultants to ensure the best outcome for your project.

We work hard to get to know your operation, the specific requirements and constraints at each distribution site, so that we can bring you tailored, added-value solutions.

We want you to end up with equipment that works for you on as many levels as possible: that enhances your loading speed and safety, optimises handling and storage capacity, dovetails seamlessly with your goods vehicles, enables you to quickly adapt to changing logistics patterns.

In short, we deliver guaranteed outcomes – solutions that generates real efficiency gains and cost savings for your logistics operation.

We consult with our customers throughout every stage of a project, from the grassroots up – with your loaders and drivers, H&S personnel, architects, maintenance teams, distribution and transport managers.

In short, we engage with all stakeholders to guarantee that you get results that work for all parties. As part of this process, we offer product demonstrations and compatibility trials at your sites and/or Transdek’s factory.

We gather as much relevant information as possible so we can offer proactive design input and help to ensure optimal outcomes for your project. And we offer advice based on over 20 years’ engineering experience in the loading bay and logistics sector.

Enquire Now

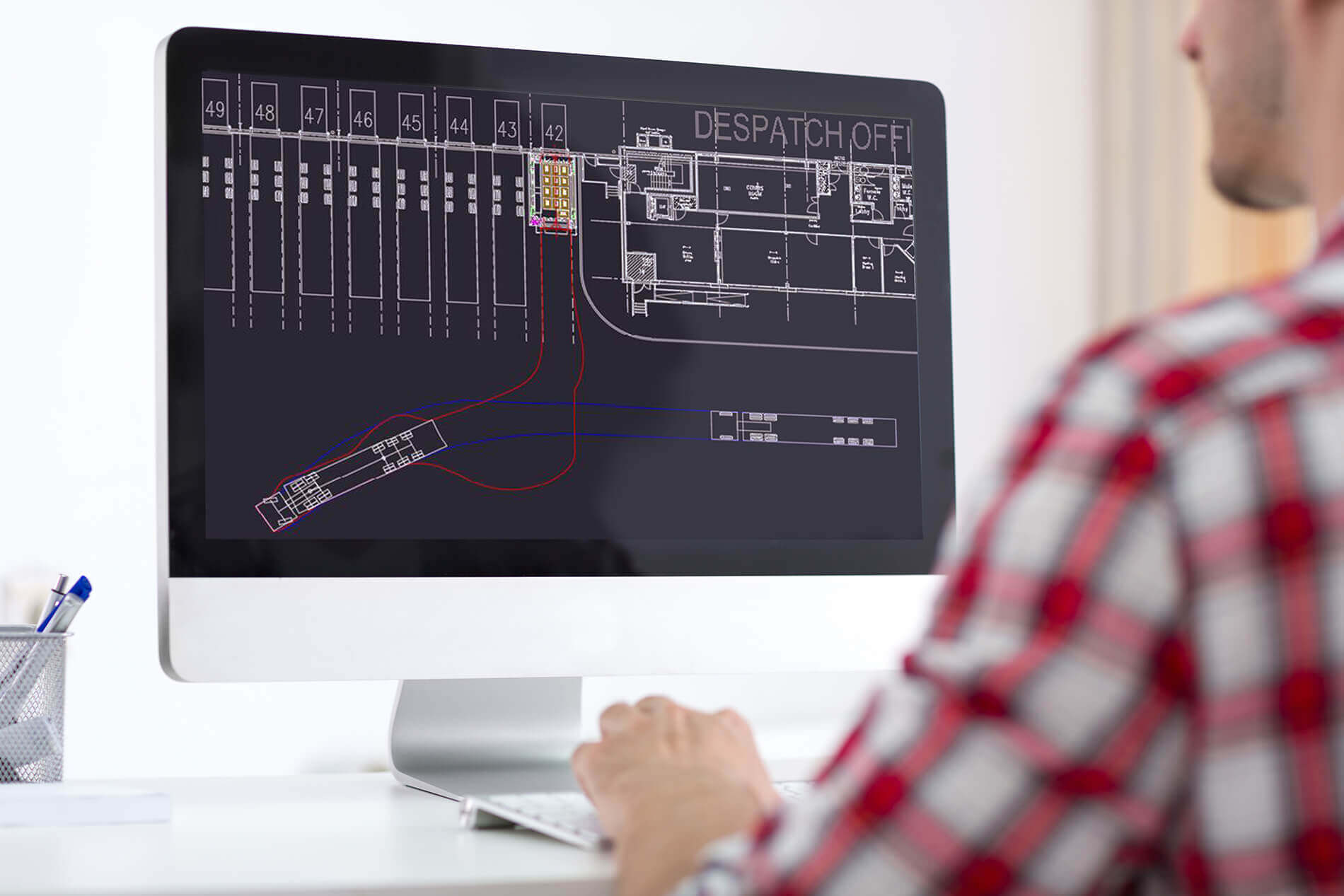

Part of the consultancy process, our feasibility studies are about guaranteeing the best product and solution designs for each site and for your overall distribution operation. We carry out comprehensive site surveys, taking into account your current and projected product flows and space utilisation; vehicle accessibility and storage requirements; installation constraints; overall cost efficiency; and all-party safety.

And based on this information, and close partnership with all project stakeholders, we offer a range of design options for you to choose from.

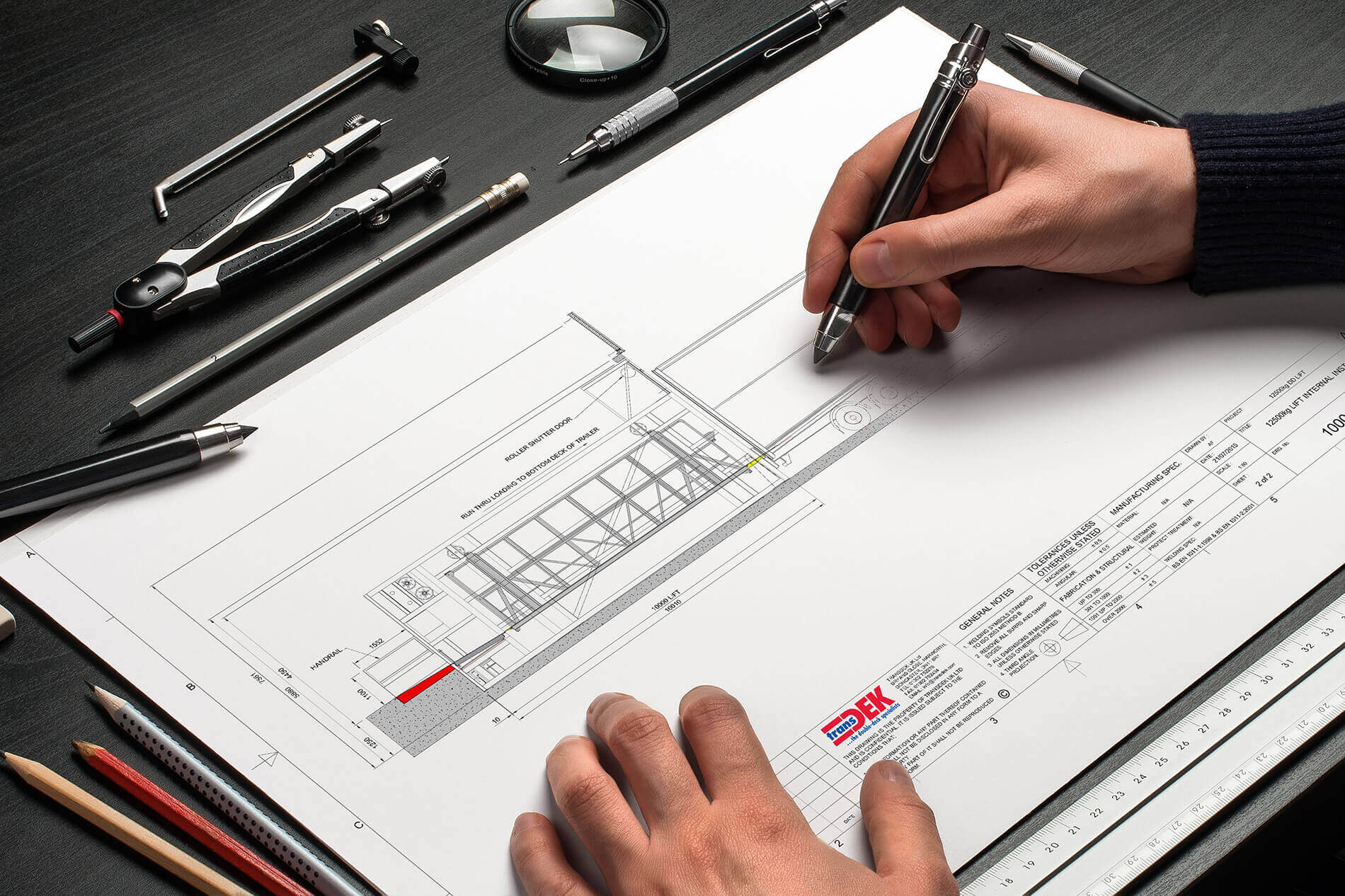

All Transdek products and bespoke solutions are designed in-house by our team of engineers. Whether working with architects on the design of a new distribution hub or a back-of-store retrofit, customising a product to match your specific operation, designing a bespoke warehouse extension, or developing the latest advances in loading bay technology, we always strive for excellence.

All our designs are structurally engineered to ensure you get a lifetime of reliable service. We are able to supply all designs in your required 2D and 3D formats.

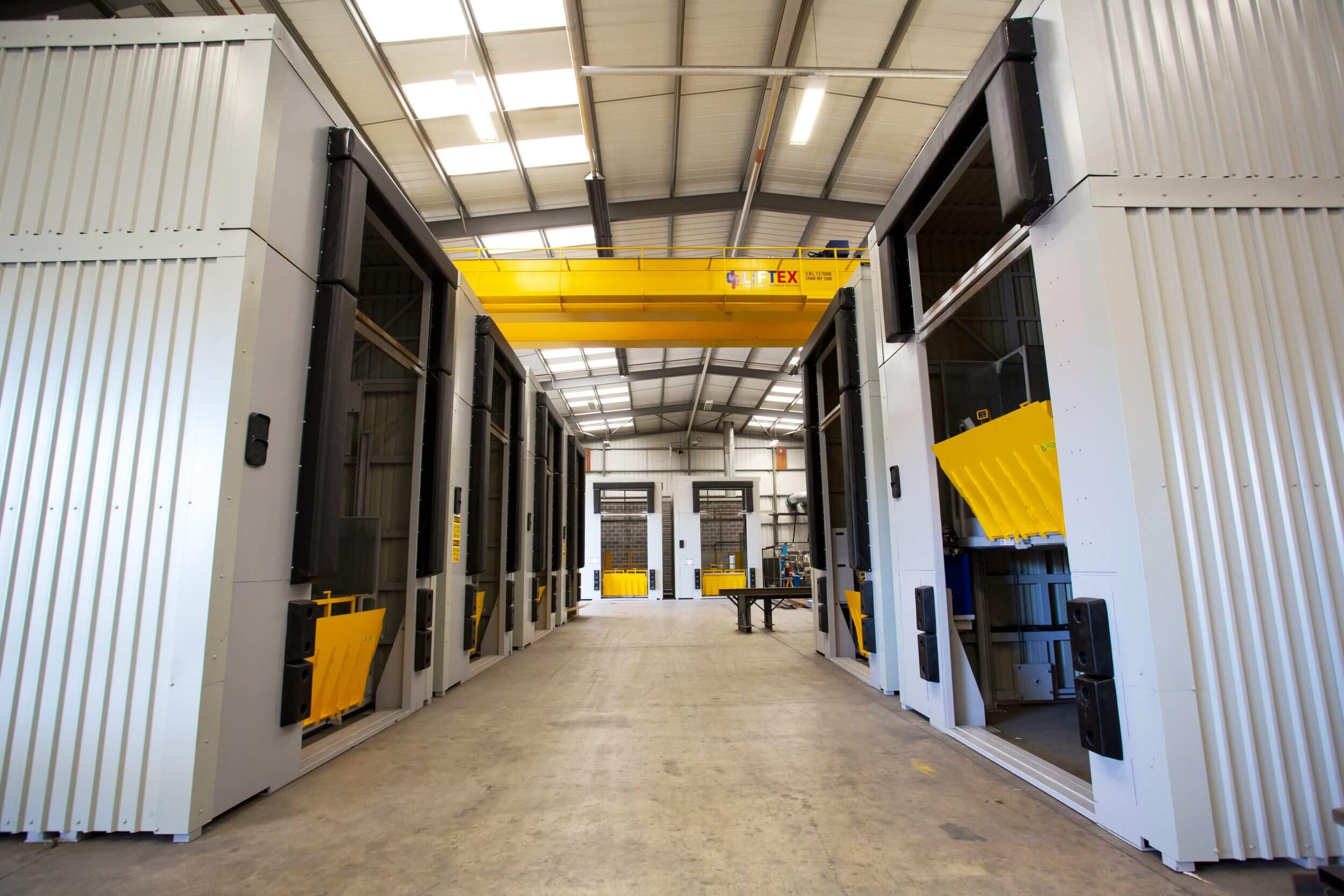

All of our loading bay equipment is manufactured to the strictest quality standards at our South Yorkshire production facility. By keeping design and manufacture under one roof, we are able to drive a continuous innovation programme as well as offering bespoke designs and customised products. Our modular products are built for a lifetime of rugged operation in the loading bay. We always welcome visitors for pre-arranged tours of the factory.

Enquire Now

Our unique range of modular loading bay products is designed for rapid installation, so we can fulfil each project on time, within budget, and with minimal onsite cost and disruption. We can hold stocks of machines off site ready for scheduled fitting to prevent congestion during new-build projects and to facilitate short lead times.

Transdek is Constructionline Gold and SafeContractor accredited, and our install teams are qualified to Level 2 NVQ in Specialist Installation Occupations (construction) – Loading Bay Equipment, and CSCS-certified. According to their roles, they are also IPAF PAL-trained.

Because it’s surface-mounted, our modular loading bay equipment can be quickly and cost-effectively uplifted and moved to a new site to accommodate downstream logistics restructuring. This saves on both dilapidation costs and capital spend on new loading equipment. And it gives you a high level of operational flexibility.

If there is any doubt about how well our loading bay equipment will work with your fleet and for your operators, we encourage all of our customers to bring their trailers to our production facility to carry out a compatibility-testing loading trial. As well as checking vehicle-to-lift compatibility, this gives managers, H&S personnel and engineers a chance to get hands-on with the equipment and to see the manufacturing process from start to finish.

ENQUIRE NOW